The manufacturing sector is growing by leaps and bounds. Take a close look at any field. It now uses small printed circuit boards instead of conventional boards. As a result, the size of devices is getting smaller and smaller. With the decrease in size, the cost has come down to a great extent. Also, the applications of devices have reached many sectors. So, what accounts for this size reduction? This is where PCB manufacturing comes into play. Let’s find out more about PCBs and the benefits thereon.

What is PCB manufacturing?

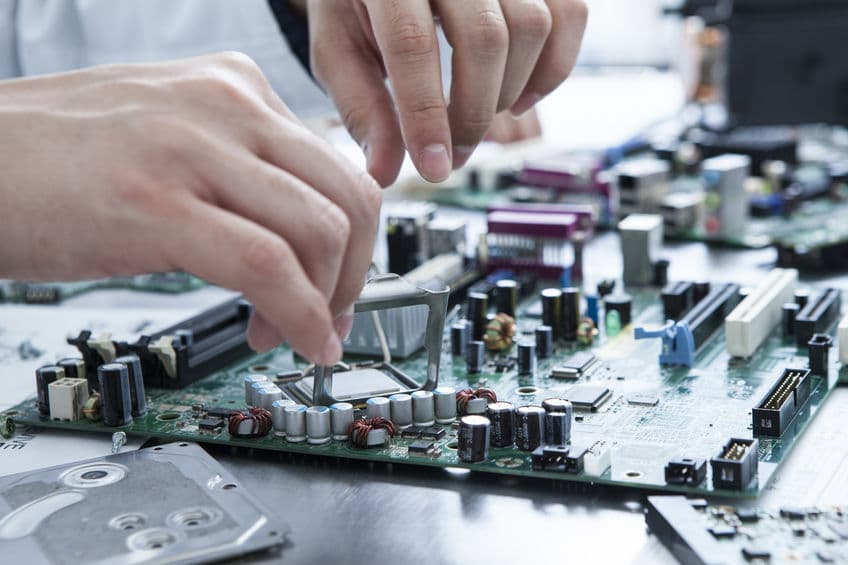

PCBs or printed circuit boards are tiny boards that you find in most electronic components. They’re the functional building block of electronic devices. Popular examples include connectors, semiconductors, diodes, capacitors, and resistors.

Benefits of PCB manufacturing

At this point, you know what PCBs are. So, you’d like to get into the manufacturing process. Essentially, more and more individuals are seeking a bright future in this sector. As a smart individual, you’d like to be one of them. So, let’s check the varied advantages of testing your skills in this sector.

Huge demand

The demand for electronic items keeps increasing. Whether it’s a TV, Smartphone, or computer, people use these devices for their activities. In the past, a small portion of individuals would use these appliances. However, the reduction in the size of electronic items and their applications account for an increase in usage. Also, the population keeps growing with time.

So, there’s huge potential for printed circuit boards. Essentially, the demand for PCB is derived from other items. Even if one electronic item doesn’t pick up for some reason, the demand for other items will elevate with time. So, investing in PCB manufacturing appears to be a better bet. You could scale your venture even during slack times.

Low competition

The modern business world is characterized by stiff competition. Whether it’s a small hairpin or a computer, you’ll find immense competition to win customers. However, each of these fields requires PCBs. If you sum up the requirements, the potential is massive.

Despite this point, there’s low competition in PCB manufacturing. The industry is still in its infancy stage. Also, finding a reliable PCB manufacturer is difficult. So, you can start your business with minimum hassles, thanks to less competition.

Higher profit margin

Older circuit boards are larger. Also, they were manufactured on a small scale. So, the cost of production was high. Plus, the demand for those boards is less. All these parameters impact the profit potential of conventional board manufacturers.

Modern PCBs are smaller in size. They take up very little resources. Also, the high demand makes a favorable scenario. So, the profit potential per unit is higher. Even if the market falls, you can survive and still earn enough money by adjusting the profit margin.

Bottom line

The above points clarify why PCB manufacturing is profitable. Huge demand, low competition, and higher profit potential are the highlighting perks of being a PCB manufacturer, like avanticircuits.com. So, don’t wait; start now and register your success.

Adam Smith Doe is an electrical engineer and PCB assembly enthusiast, known for his passion for creating eco-friendly printed circuit boards. Find out more at RUSH PCB